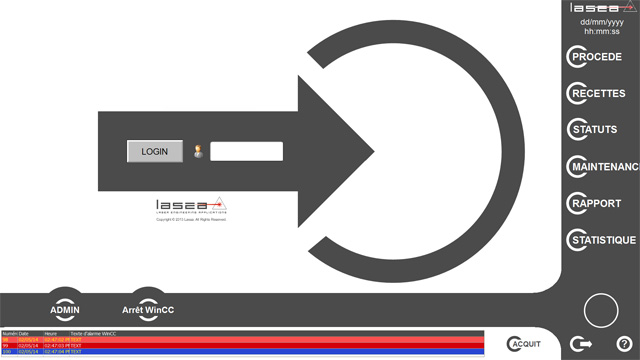

The LS-HMI software is specially designed for industrial production operators using LASEA machines.

Our intuitive and touch-friendly interface simplifies and ensures the reliability of how you manage and monitor your production operations.

With LS-HMI, you can easily design production recipes by choosing from a list of predefined actions such as autofocus, power monitoring or vision, and define the layout of your production fixtures. You can also visualize detailed production graphs and perform maintenance operations effortlessly

Here are the detailed features of LS-HMI:

Touchscreen

- LS-HMI supports an intuitive touchscreen interface, enabling smooth and natural interaction for industrial operators.

User management

- LS-HMI offers user management capabilities, allowing different permissions based on user roles. We offer standard roles like production operators, production setters and maintenance operators.

Production launch

- Displays current Production Order data, recipe details, and detailed production status. Displays machine status (alarms, errors, faults) and detailed statistics.

Recipe creator

- LS-HMI features a recipe creation tool that allows defining the production platform and designing the complete production sequence with necessary actions, including power verification before production starts, automatic positioning via vision, in-process audit operations, and serial number management.

Audit trail

- LS-HMI features a comprehensive audit trail functionality, which meticulously records all actions and modifications made within the system. Every operation, from parameter changes to maintenance interventions, is tracked with detailed timestamps and user information. This traceability ensures complete transparency of operations, supports compliance with industrial standards, and enables in-depth analysis when necessary.

Customization

- LS-HMI can be customized according to specific user needs, whether in terms of appearance or specific functionalities tailored to the client’s machining process.