-

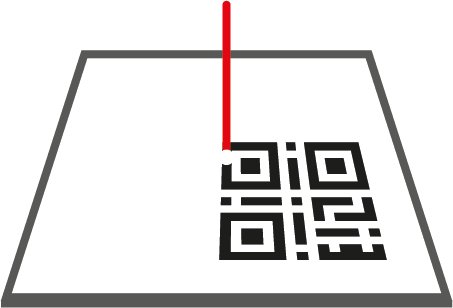

Laser marking

Laser marking consists in permanently modifying the contrast of a surface. This process is flexible, clean (no additive), contactless (no wearing) and maintenance free.

-

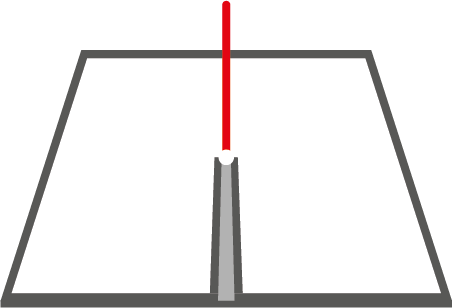

Laser engraving

Laser engraving enables fast and contactless machining of embossed designs with perfectly monitored dimensions.

-

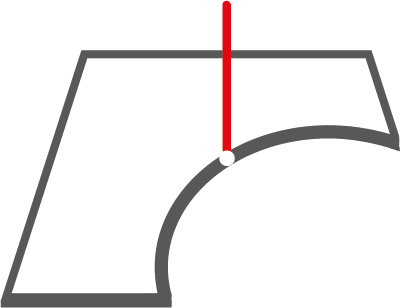

Laser cutting

Laser cutting applies to all materials (hard, fragile, soft, etc.). This flexible and contactless technique offers clean and bumpless cut walls.

-

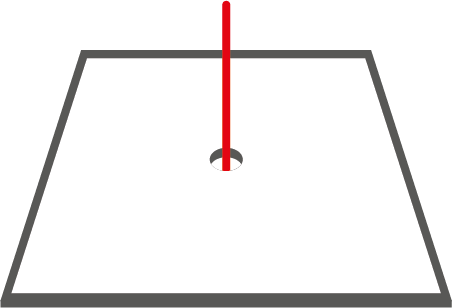

Laser drilling

Laser drilling is a fast and precise way of producing a vast type of holes

-

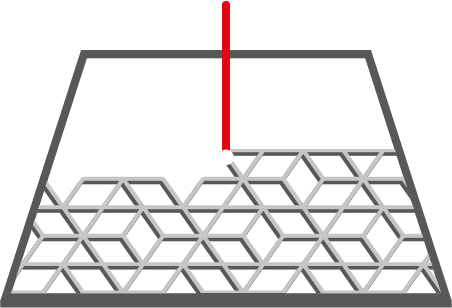

Laser structuring and texturing

Laser texturing and patterning offers decoration or functionalization of all materials surfaces by fine and high speed engraving for either simple (lines) or complex patterns.

-

Laser thin film removal

Laser thin film removal enables selective engraving without delamination, bumps or microcracks.

-

Chamfering

Chamfering is the removal of a burr or a sharp edge. The resulting bevel is then polished to improve either the movement of the part or its aesthetics by creating a play of light. Particularly appreciated in watchmaking and jewellery, chamfering guarantees impeccable results on the most delicate materials.

-

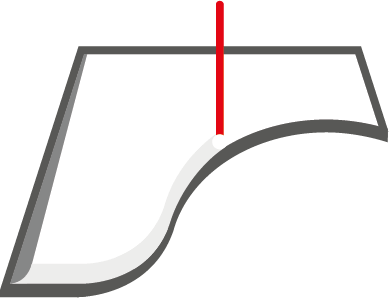

Debonding

Laser Lift Off (LLO) refers to a process in which thin layers of material are separated from a substrate, for example a polymer deposited on glass, using a laser beam that generally emits in the ultraviolet. The main requirement for successful LLO is that the substrate is transparent at the working wavelength and the target layer is opaque.

-

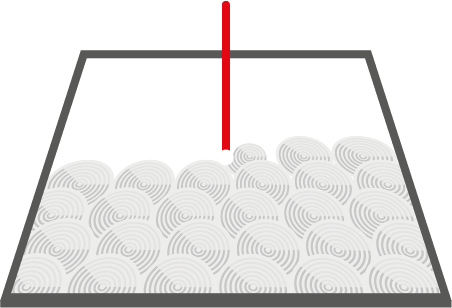

Perlage

“Perlage”, “soleillage”, polishing, sandblasting or “Côtes de Genève”... all possible decorating techniques using lasers.

-

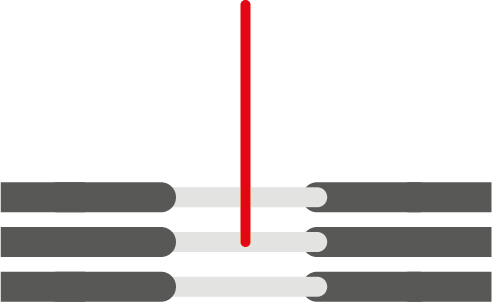

Wire stripping

The aim of laser wire stripping is to selectively remove the insulating sheath without damaging the wire or wires encapsulated inside. This extremely precise technique is used in the electronics and medical industries, mainly to strip wires that are much smaller than a human hair.

-

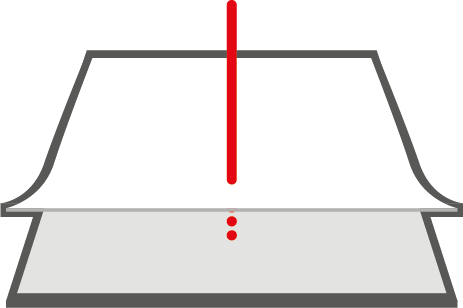

Welding

Laser welding is a process that heats the material with a high density of energy. This thermal power is focused on the parts to be joined, generating a thin, penetrating bead. Cooling the material then ensures immediate solidification.

-

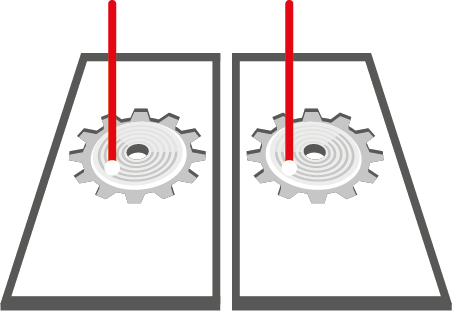

Synchronised Machining

Simultaneous Machining was developed to enable manufacturers to optimise their production volumes by dividing a single laser beam into several scanner heads to make two or more identical parts at one time.

-

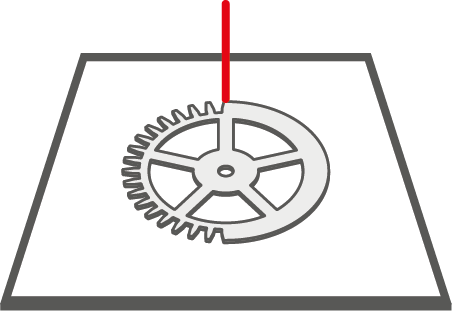

Teeth Cutting

Laser teeth cutting enables gears and gearwheels to be created with ultra-fine precision. This process, adapted to a variety of materials, guarantees strict tolerances and optimum mechanical performance, meeting the precise requirements of industry.

-

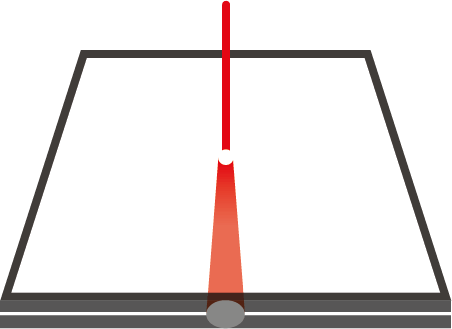

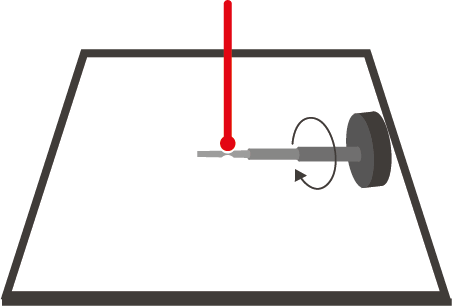

Turning

Laser turning uses an exceptionally fine beam to remove material with micrometric precision. This tool-free process is ideal for working difficult materials at fine diameters and producing perfect finishes to the highest industry standards.

Applications

Our laser applications

.