What is laser drilling?

Drilling is the process of removing material over all or part of the thickness of a work piece. The drilling is called through-drilling if the entire thickness is ablated, or non-through if only part of the thickness is removed.

Several laser drilling processes

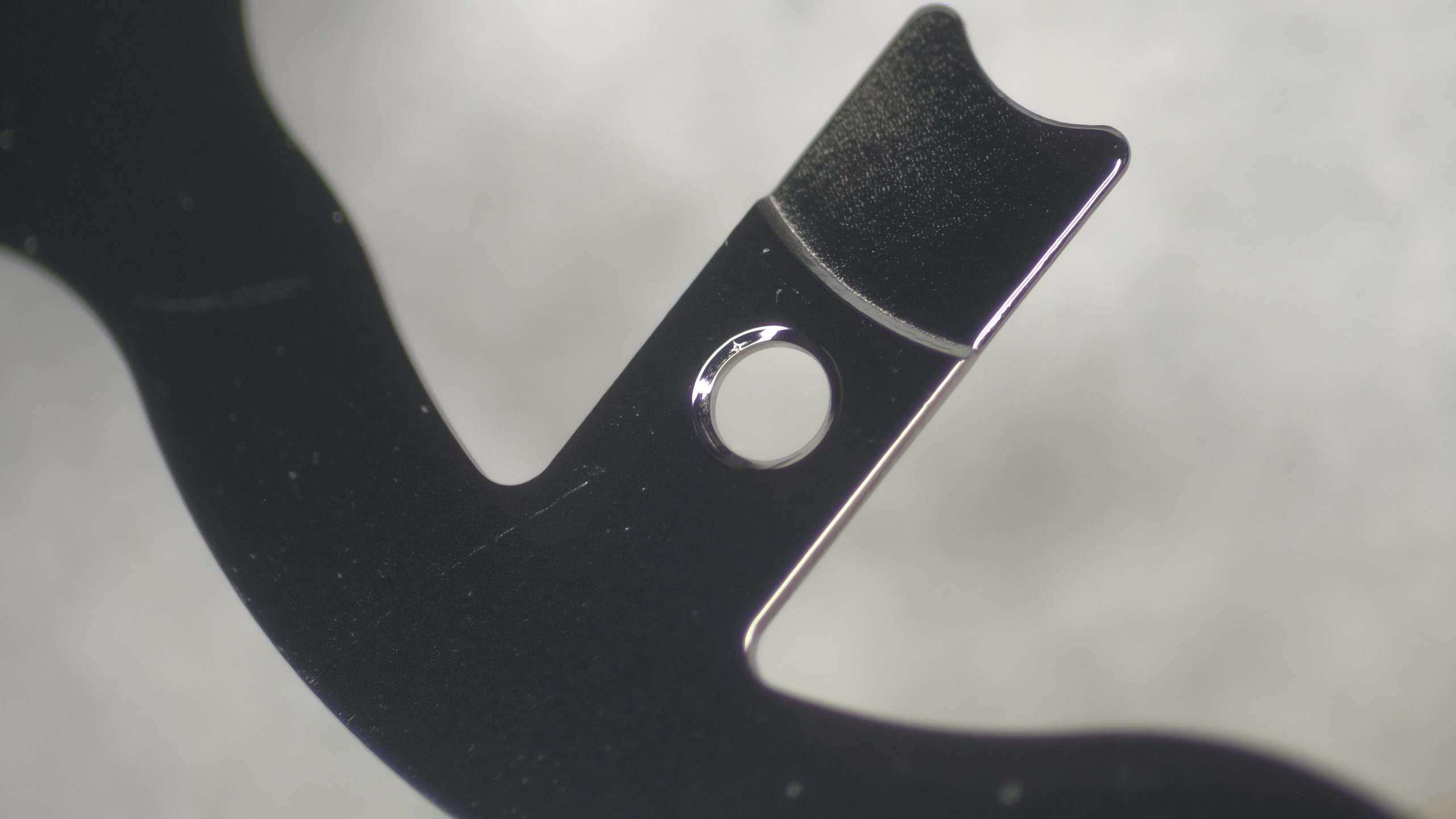

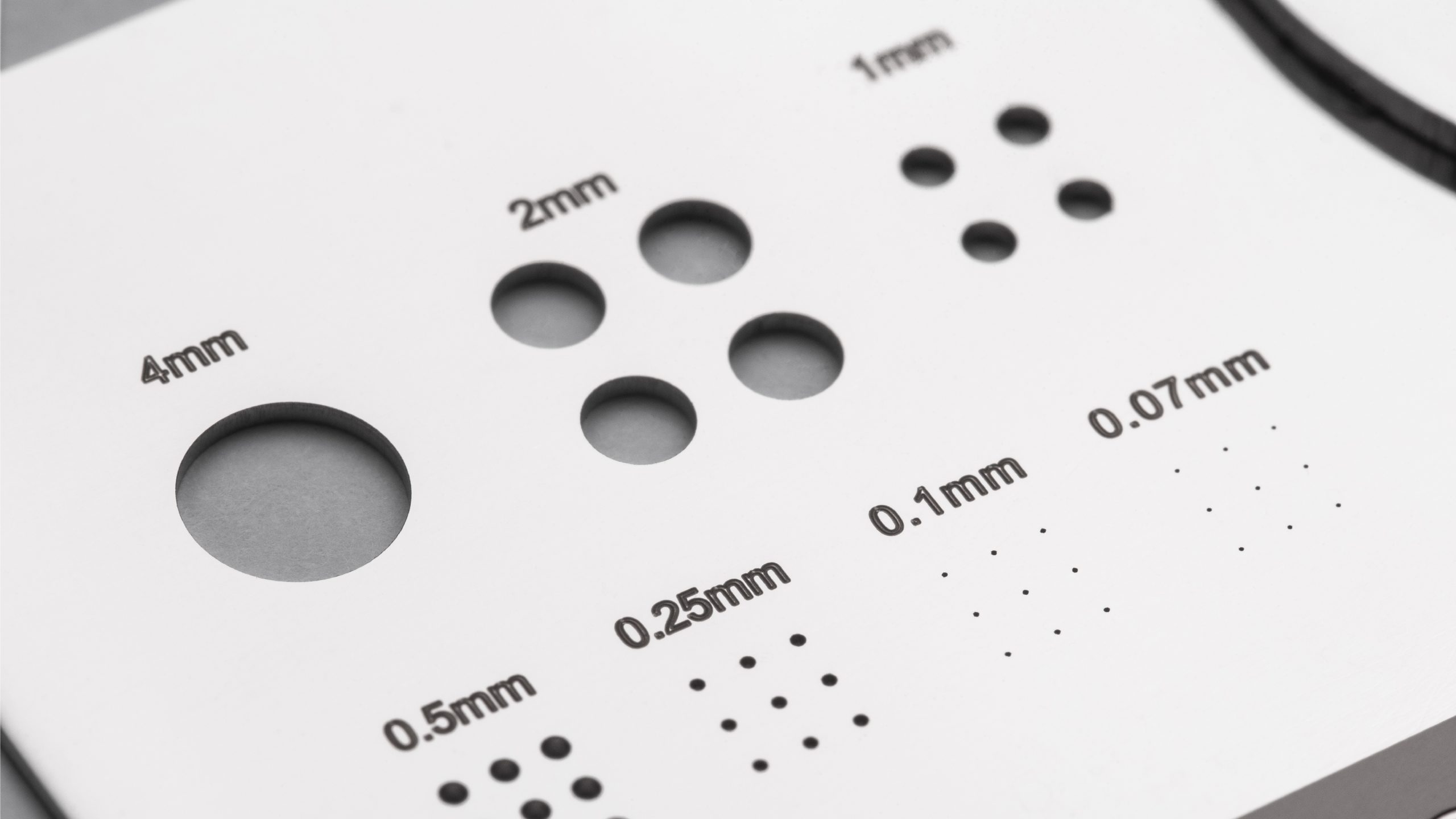

Laser drilling can be done using several methods. The first, percussion drilling, consists of firing at a fixed location using a pulsed laser, focused on a size slightly smaller than the hole to be drilled. It is with several pulses that the work piece will be drilled over its whole thickness. Drilling by cutting consists of moving the beam along the perimeter of the hole to be drilled, in one or more passes. Helical drilling is similar to drilling by cutting but comprises a movement of the focal point towards the base of the hole throughout the drilling. Finally, precession drilling, often wrongly called “trepanation”, consists of changing the angle of incidence of the beam throughout the drilling in order to compensate for the natural conicity of a laser-drilled hole. In this way perfectly straight holes can be drilled.

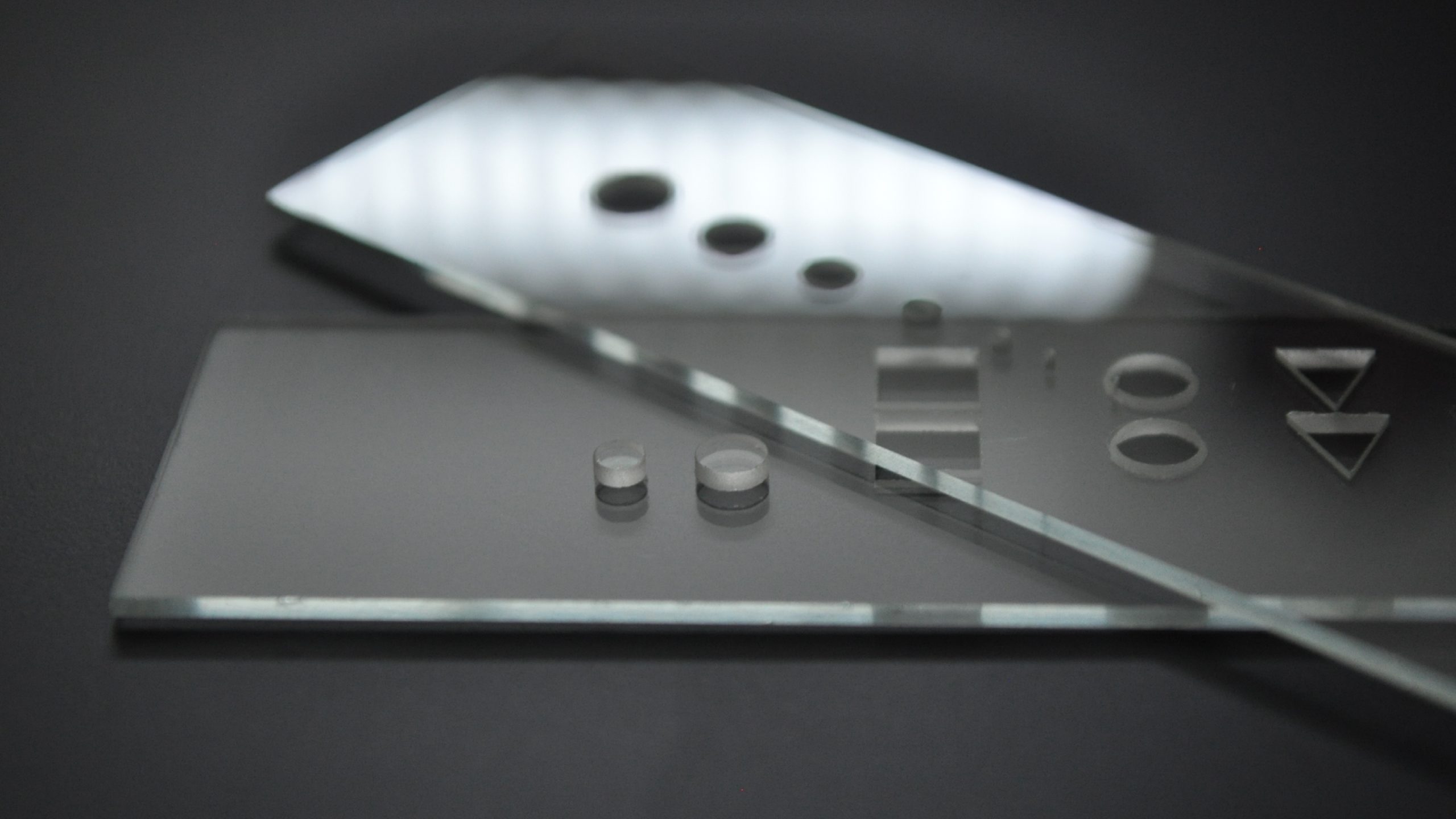

For all materials

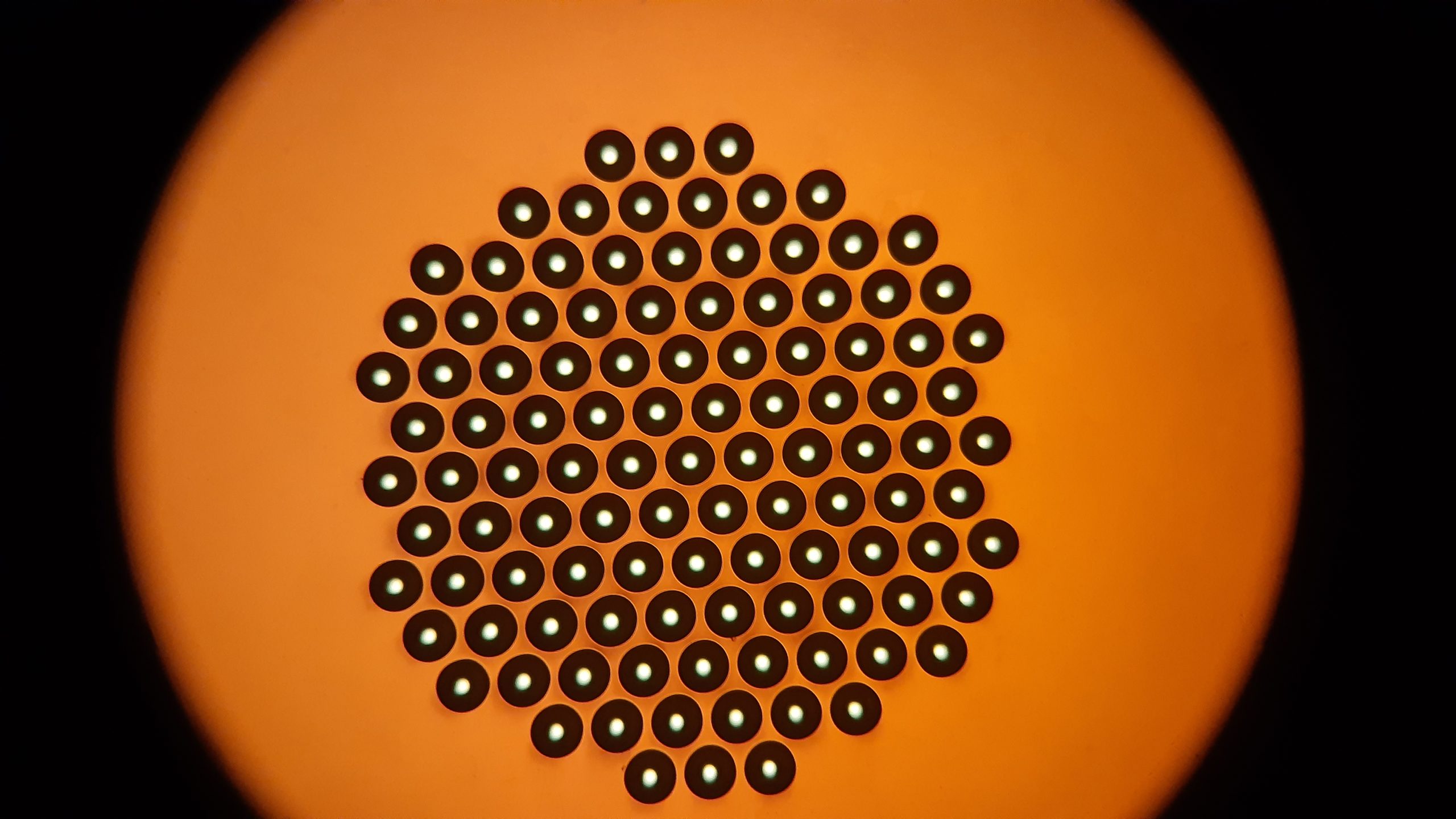

Laser drilling can be applied to all materials, even the hardest or most fragile. The results are very clean holes, without burring or carbonisation. The dimensional control, whether of the diameter, the depth or relief angle, opens up new applications that were previously out of reach, in particular in terms of the hole density.

Laser drilling is thus logically applied to the drilling of injectors, nozzles, electronic cards, etc.